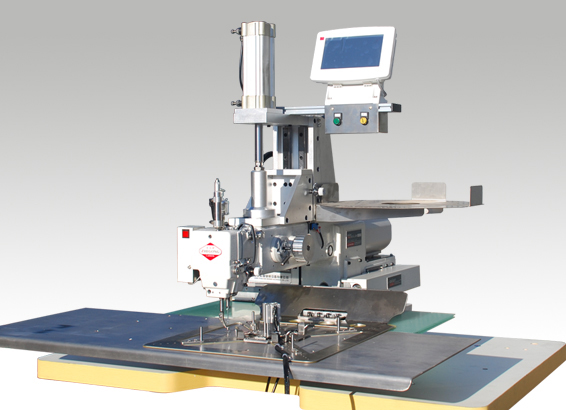

Zqk367-6050 electronic pattern sewing

machine is specially designed for sewing large-scale thick materials in the industries of container bags, bags, shoes and hats, household goods, sports equipment, automobile interiors and so on. Equipped with high-precision servo control system, high-performance servo motor drive, in the specified range can be arbitrarily set sewing style. This machine is designed with strict structure and reliable transmission precision. It can be used to set various parameters such as pattern figure, needle number, thread length and so on.

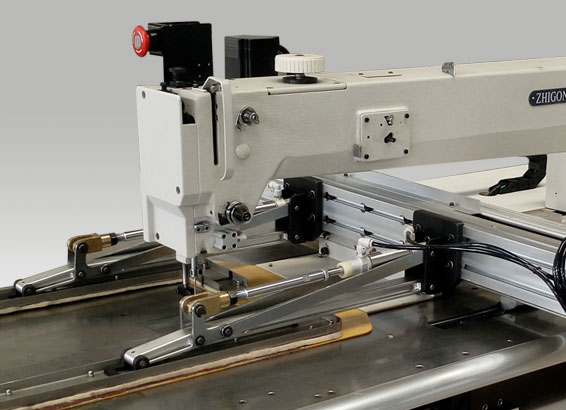

ZQK367-SJ4020 container petal sewing

special computer pattern machine newly designed by Zhiqiang Company, the head can lift the extra-thick material pattern machine, the operating space under the arm can reach 420 mm, the head can lift and drop up to 100 mm, so it is convenient to collect and drop the material, innovative lifting structure and transmission structure design, in the head to obtain stable power and pressure at the same time, sewing speed up to 1200 rpm. Equipped with automatic cutting and automatic winding functions, so that sewing work more stable. Using five times of super shuttle, bobbin thread, the use of very thick high-strength polyester sewing thread can also ensure sewing efficiency. Adopting step-by-step closed-loop computer control system, free programming, according to customer requirements at any time design, download and storage of new patterns, effectively save labor, greatly reduce the dependence of enterprises on skilled workers. At the same time, the machine adopts pneumatic lubrication system to reduce the maintenance time and extend the service life of the machine. The production clamp is specially designed for the sewing link of the inlet and outlet of the container, which can sew the“Petal” part of the container easily.

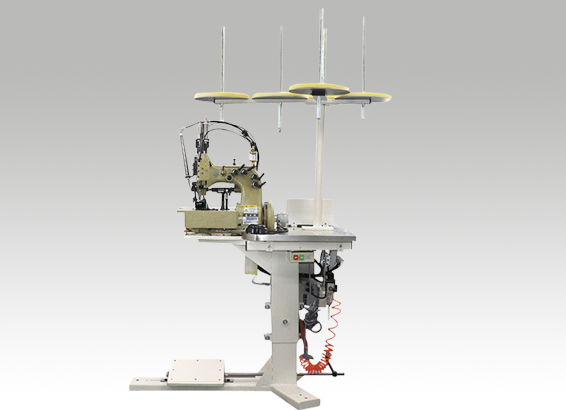

QK2600-T2010 special computer pattern machine for container sling ring adopts imported five times super shuttle, large shuttle core thread and very thick high strength polyester sewing

thread to ensure sewing efficiency. Adopt step-by-step closed-loop computer control system, free programming, according to customer requirements at any time to design, download and store new patterns, effectively save labor, greatly reduce the dependence of enterprises on skilled workers. The use of pneumatic lubrication system, reduce maintenance time, extend the machine service period. Customized production according to different materials, lines and manufacturing requirements to ensure that the equipment can fully meet customer sewing requirements, a new partner service plan to ensure that products in the use of the processwithout worry.

Zqk367 -6020 electronic pattern sewing machine is easy to input, save, modify and call patterns, and can input pre-programmed graphics through USB interface for sewing processing. Is a specialized for sewing leather, lifting belt and other thick materials of large-scale electronic pattern machine.

ZQ9810 type upper and lower compound feed extra-thick material sewing machine adopts single-needle swing shuttle, which forms double-thread lock thread, lifting feed tooth, exchange presser foot, sticky and sewing longer products, to ensure that the upper and lower layer, so that products neat, beautiful stitching. Connecting rod take-up mechanism, so that the spindle rotation can be increased, reduce the sound, ensure the overall quality, extend service life.

GSC -367 sewing machine

GSC -367 D has the function of manual reinforcement and automatic speed reduction. When the operator carries out the manual reinforcing seam, the high speed will automatically drop to the speed range set in advance. The new worker can lower the speed of the manual reinforcing seam, and then adjust it again after he is skilled, this kind of humanization design more adapts the enterprise to the new staff fast training need. Applications: container bags, military products, large tonnage lifting belts, high altitude operation safety equipment, sports equipment, fall protection supplies, straps, tensioners, synthetic fiber lifting belts, complete sets of rigging, industrial lifting belts, safety belts, hanging ropes, sofas, harness, parachutes, tents, sails, military lifting belts, truck covers, etc.

80700CD4H double needle sewing machine this machine is specially designed for the production of container bags double needle four thread chain sewing machine, unique accessories design, so that sewing space is larger, can be smoothly sewn to the container bags, it is easy to sew up and down parts such as slope and corner by using up and down feeding method. Its stable column type plate frame design is more suitable for sewing up and down leak-proof strip on container bags.

81300A1H double-needle four-thread up and down feeding chain lock sewing machine is specially designed for the production of container bags, the unique structure design enables the edge-wrapping thread trace and chain thread trace to be completed at the same time. The stable column type plate frame design is more suitable for sewing the feeding and discharging ports on the container bags, and can sew the up and down leak-proof strips simultaneously, this machine has the electric control foot lifting mechanism, which makes the operation of the sewing machine more flexible and convenient, and the sewing effect is more beautiful, the length of the cut-line fully meets the standard requirements of the container bag.

GN20-3/2 double-thread Hemming sewing machine

GN20-3 double-thread container sack hemming machine is suitable for hemp bag, PP/PE woven bag and other thickness of the bag edge; GN20 -2 double-thread carpet Hemming Machine for carpet and car mats edge sewing, using two-thread hemming, you can sew thickness of 14 mm thick carpet. Only need to change a few parts can sew curve and arc-shaped edge, and strong and durable.

Model GSC-2600 sewing machine 2600TD is specially designed for the production line of large-scale container bag and ton bag manufacturers, greatly reduce the labor intensity of employees, while in the sling sewing process to achieve the same anyway, greatly improve the quality of container bags, this machine is the ideal choice to realize the goal of high speed and high quality of container sewing.

GSC2600-25 upper and lower compound feed extremely thick material sewing machine applications: military products, large tonnage lifting belt, high altitude operation safety equipment, sports equipment, falling protection supplies, binding belt, tensioner, synthetic fiber lifting belt, complete rigging, industrial lifting belt, safety belt, hanging rope, sofa, harness, polishing wheel, hemp wheel, parachute, tent, sail, military lifting belt, truck cover, etc.

Model SGB4-1/4-3 upper and lower compound feed sewing machine (canvas sewing machine) uses single-needle swing shuttle to form double-thread lock stitch, lifting feed tooth, exchange presser foot, this mechanism under any length of needle pitch within the rated range, when sewing slippery, sticky and sewing specialty products, can ensure the upper and lower layer, make products neat, beautiful stitching. Connecting rod take-up mechanism, so that the spindle rotation can be increased, reduce the sound, ensure the overall quality, extend service life. Uses: hemp wheel, polishing wheel, truck tarpaulin, canvas, tent, container bag, ton bag, space bag, safety sling, industrial sling, synthetic fiber sling, harness, quilt, saddle and other thick material products.