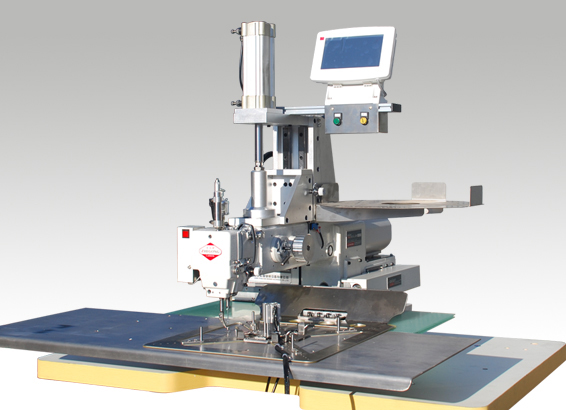

ZQK467-GY5020 Container bag lifting ring sling integrated machine

Product Features:

This machine is an automatic sewing computer pattern machine specially research and produced by our company for sewing container bags feeding port and discharging port. This machine uses three times the super-large rotating hook, the bobbin core can contain a large number of thread and ensures the sewing efficiency when using 800D high strength polyester sewing thread. The system adopts Beijing Dahao's step-by-step closed-loop computer control system, which can be freely programmed, designed, downloaded and stored new patterns at any time according to customer's requirements, and the machine head can automatically rise and fall, and the operation is safe and convenient. The folding device specially designed for the feeding port and discharging port of container bags can be adjusted freely between 100mm and 150mm, which saves labor, time and labor. The product quality processed by this device is stable and the work efficiency is high. At the same time, the machine adopts Japanese SMC pneumatic components, and the guide rail adopts Taiwan HIWIN brand, which greatly reduces the maintenance cost and prolongs the service life of the machine.

The new partnership service plan ensures that there are no worries in the use of products.

Technical Parameters:

Model: | ZQK467-GY5020 |

Optional sewing range: | Xaxis (left/right)500mm; Y-axis (front/rear)200mm) |

| Maximum sewing speed: | 100-1800rpm |

Needle pitch: | 0.1-12.7mm |

| Maximum number of stitches: | 20,000 stitches per pattern |

| Storage capacity: | 900 graphics (control box memory) |

| Data storage method: | Control box memory, USB flash drive |

| Machine needle type: | DDX1#230(standard) |

| Shuttle bed: | 6 times larger automatic thread cutting rotary shuttle |

| Trimming system: | Cylinder driven or motor-driven fixed knife (optional), flat pull bite type |

| Lubrication system: | Digital system controls lubrication and injects oil into the oil box through the oil core to supply oil |

| Operating system: | Beijing Dahao 6th generation dedicated system |

| X-Y drive system: | Stepper motor control, timing belt drive, intermittent or continuous feeding |

| Cross adjustment range: | 10-12-14 |

| Power source: | 200V-240V single phase |

| Air pressure: | 0.5Mpa 1.8L/min |