Electronic pattern machines are widely used for sewing patterns in various handbags, clothing, textiles, leather goods, luggage, footwear, belts, sports and leisure equipment, etc. At the same time, it can enhance the corporate image and position. Nowadays, many major decorative customers of product brands have specified the use of needle thread and patterns. So having an electronic pattern machine is also one of the corporate images.

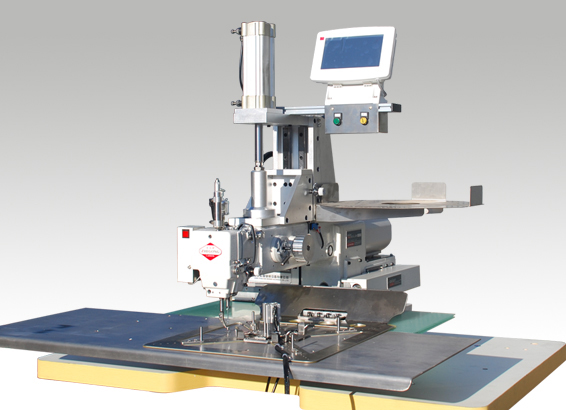

The entire machinery of the electronic pattern machine includes upper shaft, lower shaft, main shaft, needle bar, thread picking mechanism, thread cutting mechanism, hook mechanism, feeding mechanism, pressing mechanism, and other parts, with approximately 600 to 700 parts. The entire mechanical system has a complex structure, high precision, and high requirements for assembly quality.

Electronic pattern machines have a certain service life, and there is rarely any undamaged condition until the end of the service life. Therefore, certain maintenance and repair are required during this period in order to use them until the end of the mission. As a type of sewing equipment, electronic pattern machines can have high sewing technology and can sew with high efficiency in a short time. It can also avoid the fate of maintenance within the service life.

During the use of electronic pattern machines, it is inevitable that there may be some malfunctions. Once a malfunction occurs, it is necessary to find someone to repair it. For some relatively large enterprises, there is a dedicated maintenance department that conducts daily inspections of the equipment. If any abnormalities are found, timely maintenance is carried out, providing guarantee for the development of the enterprise and bringing certain economic benefits to the enterprise. Especially for some clothing production and processing factories, the use of needle sewing machines is very common. Often, needle sewing machines encounter various faults during use, and after these faults occur, specialized personnel are required to repair them. When maintaining the needle machine, it is necessary to have a certain purpose and not blindly carry out maintenance, as this may cause equipment damage.

This article is edited by www.hbzg.com