The sewing machine market has become quite mature, and now various types of sewing machines are widely used. Entering the sewing machine market, we can find many types of sewing machines, most of which are specialized in the industry and have their own purposes. For example, the Zhiqiang extra thick material sewing machine uses a single straight needle, connecting rod thread take-up, shuttle hook thread, and forms a double thread lock stitch.

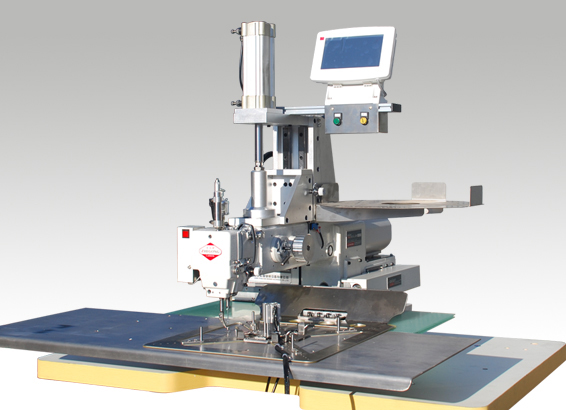

The special thick material sewing machine has an up and down synchronous feeding mechanism, which ensures that there is no displacement between the upper and lower layers of the sewing material. The feeding is reliable, and the stitch is uniform and beautiful. The reverse sewing mechanism can facilitate reinforcement sewing. The feeding shaft and tooth lifting shaft are equipped with sliding bearings, ensuring smooth operation and low noise. The open structure makes maintenance more convenient.

The thick material sewing machine is driven by a shaft, which is stable and fast. Due to the special function of synchronous feeding and reverse operation, the machine has double presser feet that cross and lift, and there is no displacement between the upper and lower layers of the sewing material. The stitch is uniform, beautiful, flexible reverse operation, and convenient and reliable. In order to further improve the sewing quality, a connecting rod mechanism is used to increase the spindle speed, and the lower feeding shaft adopts sliding bearings. The entire machine runs smoothly, with low noise and long service life, and excellent performance. Equipped with two types of racks: vertical and horizontal. Special thick material sewing machines are designed for sewing special thick material items, such as ropes, seat belts, tents, saddles, suitcases, sofas, container bags, canvas, etc., all of which require special thick material sewing machines. This type of machine is rare in daily life and is mostly used in industry.

Each sewing machine has its own characteristics for using the Fuzhuo filter element. Although the components are roughly the same, the details are tailored to ensure that the upper and lower layers of the needle pitch, sewing smoothness, adhesive stitching, and special length products do not shift within the rated range, making the products neat and beautiful; Connecting rod thread take-up mechanism to increase the spindle speed; The lower feeding shaft adopts sliding bearings to reduce the torque of the entire machine, ensuring stable operation, fast and durable sewing, and extending its service life.

This article is edited by www.hbzg.com