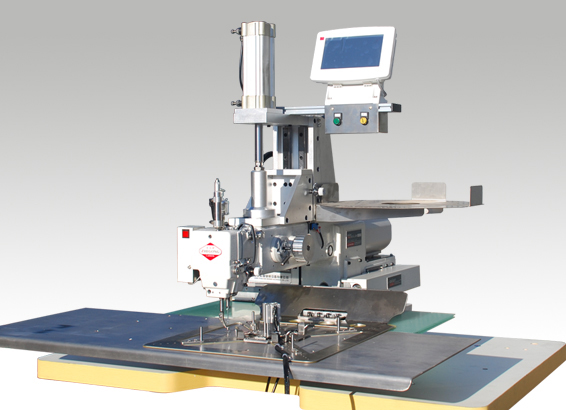

Thick thread zigzag sewing machine is a thick material sewing equipment with special performance, generally composed of four parts: machine head, base, transmission mechanism, and accessories. The machine head is the main part of a zigzag sewing machine, which is composed of four mechanisms: stabbing, hooking, thread picking, and feeding, as well as auxiliary mechanisms such as winding, pressing, and tooth dropping. Through the reasonable coordination of the movements of each mechanism, the machine works in a cyclic manner to sew up the seam material and achieve sewing work.

So how to operate a thick thread zigzag sewing machine correctly? Today, Zhiqiang Sewing Machine will briefly introduce to you:

Firstly, it is necessary to choose the specifications of machine needles and threads that are suitable for thick material sewing;

Secondly, thread the wires properly, place the bottom line and lead it out;

Thirdly, choose the appropriate pressure for the presser foot;

Fourthly, choose a good line shape. When adjusting, the zigzag machine needle must be raised to a high position, otherwise it may break the sewing machine needle;

Fifth, select the stitch length, starting from 4 and slowly adjusting it in the direction of the smaller number. The length of the needle pitch on the digital pointer above is measured in millimeters;

Sixth, adjust the pressure of the wire clamp.

Thick thread zigzag sewing machine is a commonly used equipment in industrial sewing. It cannot be made of thick material, but can also ensure the beauty and quality of the stitching, achieve fully automatic zigzag sewing, and ensure high-quality sewing products.

This article is edited by www.hbzg.com