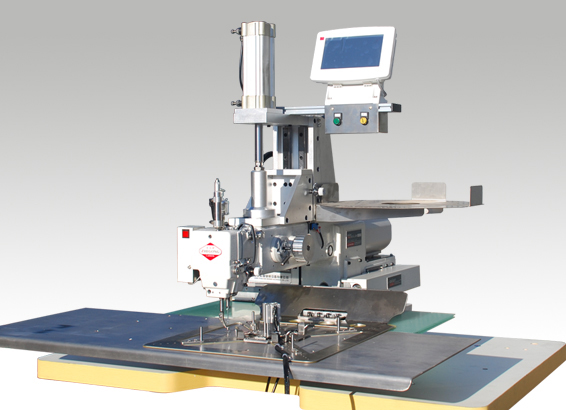

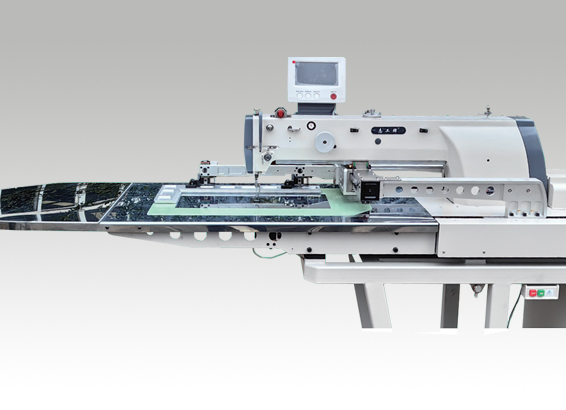

ZQK467-50 CNC Multifunctional automatic computer pattern machine

Product Features:

This machine is one of the series products of Zhigong Electronic Patter Sewing Machine, which is specially designed for sewing large-scale materials in container bags, luggage, shoes and hats,household goods, sporting goods,automobile interiors and other industries.

This machine is equipped with the Dahao VI special high-precision servo control system,high-performance servo motor drive, which can be set arbitrarily sewing style within the prescribed range, and the response speed is accurate and reliable.

Equipped with motor-driven thread cutting device, the thread cutting is more accurate and stable;

The surface of the auxiliary working platform is plated with hard chromium, which is more wear-resistant without rust and effectively avoids the pollution of white materials;

The needle bar adopts black diamond plating process, which has better wear resistance;

The synchronous belt adopts Japanese brand Bandong, which has low noise, long service life and strong transmission performance.Adopt imported high-quality solenoid valve to ensure every action is accurate and the service life is longer;

The motor gear speed adopts the gap adjustable sealed gearbox design, which ensures that the noise generated by the gear bite is not outward, and also ensures the lubrication of the gears;

The new upper and lower shaft transmission design not only effectively reduces the noise generated during the upper and lower shaft transmission, but also guarantees the convenience of disassembly and maintenance;

The novel rotary shuttle lubrication design makes the lubrication of the rotary shuttle and the front sleeve of the lower shaft more convenient and controllable, and the lubrication frequency can be adjusted through the system, and the lubrication effect can be seen;

It has strict design structure and precise and reliable transmission. It can set various parameters such as pattern, stitch number and stitch length through random programmer, and it is convenient to input, store, modify and call patters. It can also input various pre-programmed patterns through USB interface for sewing.

This model is a large-scale electronic pattern machine specially used for sewing thick materials such as container bags and lifting belts.

A new partner-based service programme to ensure worry-free product usage

Technical Parameters:

Model: | EQK467-50 |

Optional sewing range: | 500mmY-axis (left/right)500mm (factory standard 200,optional range of internal medicine), X-exis (front/reer)500mm |

Maximum sewing speed: | 1800rpm |

Set speed: | 9 stages Setup |

Needle pitch: | 0.1-12.7mm |

Maximum number of stitches: | 20000 stitches/graphics per pattern |

Storage capacity: | 900 graphics (stored in the control box) |

Data storage method: | Control box storage, U disk (non-sewing machine accessories) |

Needle bar stroke: | 53mm |

Thread take-up rod stroke: | 103mm |

Machine needle type: | DDX1#230 (standard) |

Lift amount of middle pressure foot: | 15mm (factory setting 12mm) |

Upand down stroke of the middle pressure foot: | 4-20mm (factory set 8 mm) |

| Extemal pressure plate lifting amount: | 30mm |

Shuttle bed: | Large automatic cutting machine (6 times the size of automatic cutting shuttle) |

Driving method for lifting the presser foot: | Cylinder drive |

Trimming system | Cylinder drive or motor drive (optional), fixed knife.movable knife flat tension type (slendard) |

Lubrication system: | Pneumatic lubrication + oil feed into the oil box through the oil core |

lube: | 20 silicone oil |

X-Y driving system: | Stepper motor response control, timing belt drivemade, intermittent'or continuous feed |

Video: